A solid basis - the floor plate

Written by am

A 12 cm thick plate of durable and resistant phenolic plywood serves as floor at the "living area" of our car.

The making of a new wooden floor slab was one of the first things we had tackled in the process of rebuilding our G. At this time we didn’t have the slightest idea that it would take additional 1.5 years until the floor was finally put into the car. The list of work that had to be done before fitting in the floor plate was extensive.

Although at this stage the layout and positioning of most pieces of furniture existed only in our heads, the spot for the cooler had emerged quickly. We were certain that it would be placed behind the driver's seat, where it was supposed to stand not on the floor plate but about 15 cm lower due to a G-Class characteristic small step in the bodywork there. We intended that the cooler should have the same height as the later built bench. With this, the cooler could serve as an extension of the bench and provide additional seating surface (or lying surface when the bench is unfolded to serve as bed).

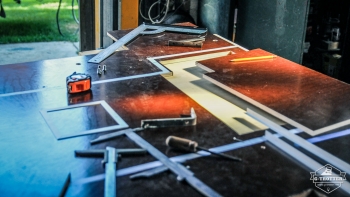

Looks messier than it actually was.

Looks messier than it actually was.For the floor slab we used a 12-mm thick phenolic plywood. The spot for the cooler as well as for the two wheel arches were cut out. Further, it had to be ensured that the tank dispenser located in the center of the vehicle remains accessible despite the floor plate, which is why we had cut out an opening of 20x20 cm dimension. A cutout also had to be done for the access to the baby bathtub. Hence, we installed a flap (with piano band) in the floor plate. Along the cutouts for the tank dispenser and the baby bathtub, we have mounted T-bars for optical reasons.

Drive-in nuts were placed in the floor slab to screw the pieces of furniture onto the plate in order to have them stably installed in our vehicle.